Penta Srl experience in nuclear power

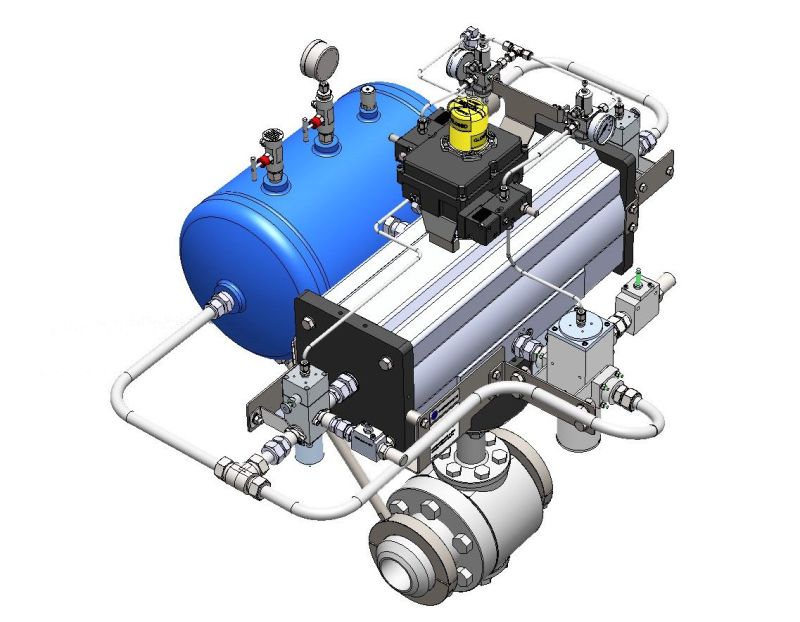

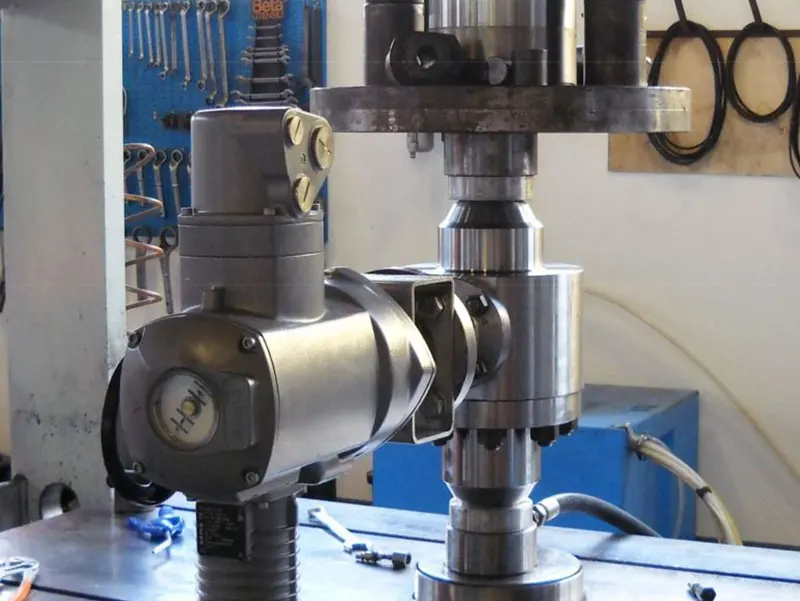

The availability of unique technologies in the field of metal seated ball valves allows us to solve very complex problems. In the case in question valves are intended of a filtration system inside nuclear power stations that must allow a high pressure and jet velocity of radioactive CO2 at 400°C. The design pressure is 5.3 Mpa, but the main problem is the stroke time that must very low.

Thanks to the specific PENTAFITE self-lubricating metallic seats and special sliding bushes for the ball trunnion, we succeded in supplying DN 3″ ANSI 600 valves with 0.9 secs 180° operating time (closed-open-closed) and DN 12″ ANSI 600 valves with less than 3 secs 180° operating time.

The low friction coefficient of the PENTAFITE self-lubricating material, which allows a 40% reduction in operating torques compared to other common carbide surface coated seats and ball, made possible to withstand the high sliding speeds. At the moment the valves are still in service without the need for maintenance and with no reported issues.