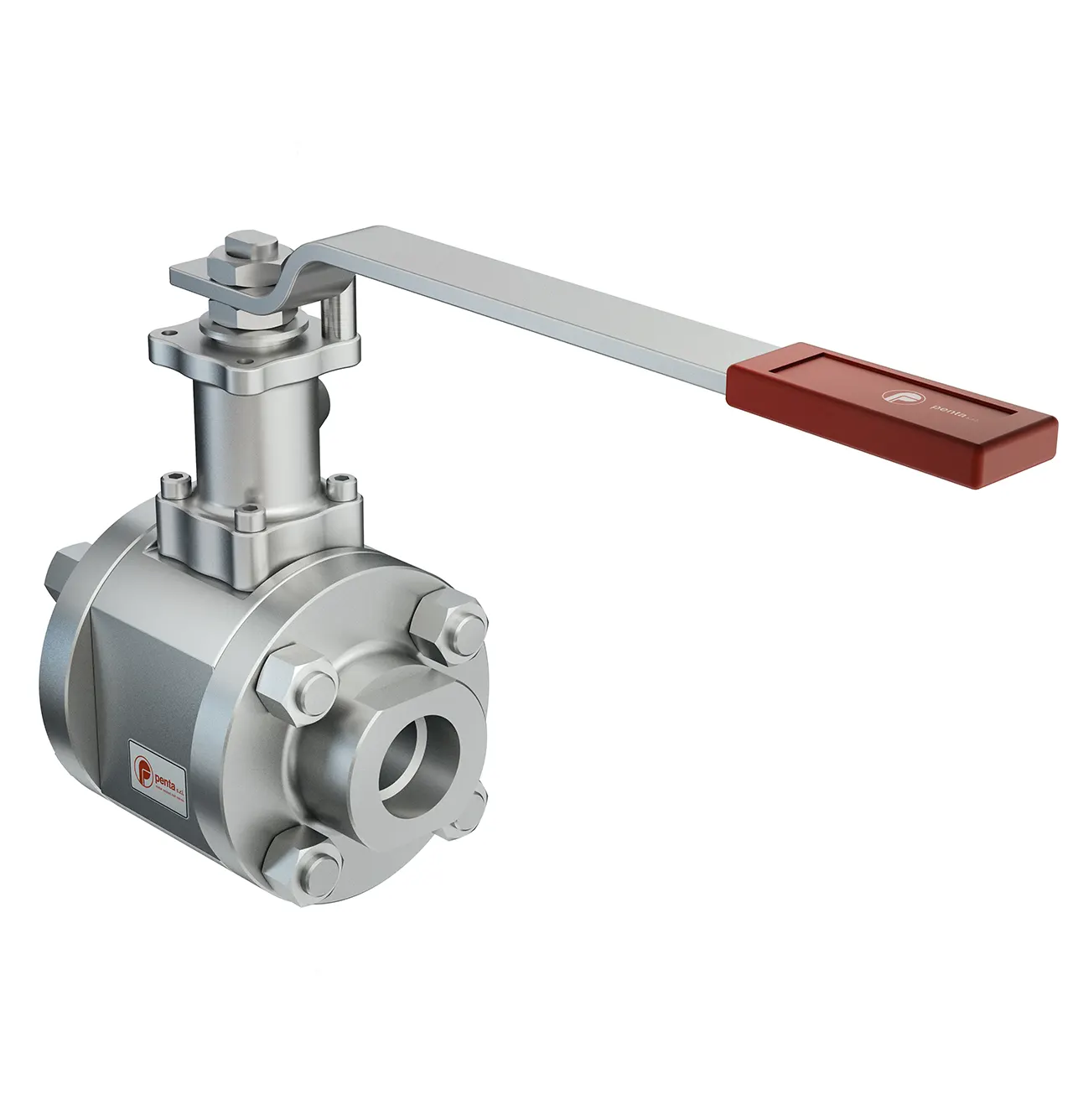

Wafer ball valve for medium temperatures from -50 ° C to + 400 ° C with soft or metal seats

This model can be considered an evolution of the historic Penta Wafer construction models, designed to make the maintenance of this type of valve easier, especially when used on particularly dirty services.

Technical features

| COSTRUZIONE | Sfera Flottante, Passaggio Pieno, Wafer |

| RANGE DIMENSIONI | DN 1/2” – DN 6” |

| CLASSI DI PRESSIONE | ANSI 150-600 PN 10-100 |

| RANGE TEMPERATURA | – 50°C / +400°C |

| DESIGN STANDARD |

ANSI B16.34 / API 608 / ISO 14313 / EN17292 / ASME VIII Div.1EN 12516-1

|

| SCARTAMENTO | EN 558 serie 100/101 e 107 |

| ESTREMITÀ | ASME B16.5 / EN 1092-1 |

| MATERIALI CORPO | A105 / A350 LF2 / AISI 316 / AISI 304 / altri materiali su richiesta |

| SEDI DI TENUTA | PENTAFITE / WC / CRC / ST6 / RPTFE /TFM / PEEK |

| COSTRUZIONE STELO | ANTI BLOW-OUT |

| MOUNTING | ISO 5211 |

| CLASSE DI TENUTA | ASME B16.104 / API 598 Cl. A / EN 12266-1 / ISO 5208 / GOST54808 Cl. A |

EC Directive 2014/34/UE “ATEX”

TA-LUFT Approved (solo se con prolunga stelo)

FUGITIVE EMMISSION ISO 15848-1 (solo con prolunga stelo)

STEM TIGHTNESS

The double spring system and tightening nuts (live loading) allows to provide the correct preload to the rod seals, to recover wear and expansion differentials between rod and body.

SEALS

High temperature resistant Grafoil ® gaskets are used.

STEM

The stems are 100% oversized compared to the expected torque at max. DP rating.

The use of the Split Body construction allows easier assembly and disassembly operations and avoids the likelihood of seizure of the threaded closing rings. The automatic discharge of overpressures in the valve body together with the bi-directional feature make the model technically performing.

WSS: floating ball flat body valve

WSJ: flat body floating ball valve with intergal heating jacket

| INTERVALLO DI PRODUZIONE | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ancora in fase di modifica | ||||||||||

| ANSI B 16.34 | 150 | 300 | 600 | 900 | 1500 | |||||

| PN | 16-25 | 40-50 | 64-100 | 160 | 250 | |||||

| Diametri Nominali | F | T | F | T | F | T | F | T | F | T |

| ½” | ||||||||||

| ¾” | ||||||||||

| 1” | ||||||||||

| 1¼” | ||||||||||

| 1½” | ||||||||||

| 2” | ||||||||||

| 2½” | ||||||||||

| 3” | ||||||||||

| 4” | ||||||||||

| 6” | ||||||||||

| 8” | ||||||||||