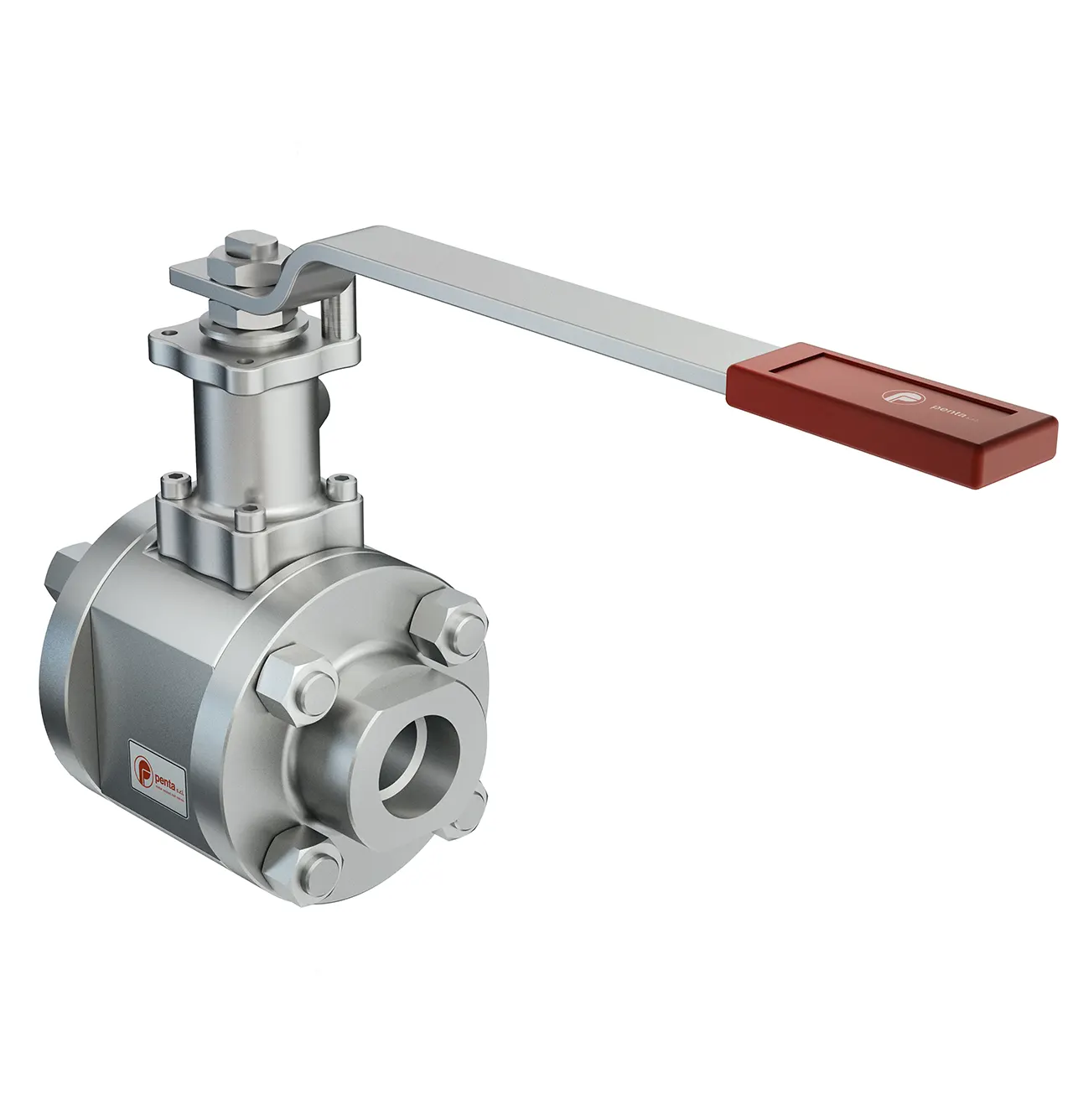

2-piece threaded ball valve for medium temperatures from -50°C up to +400°C available with soft or metal seats

AP20P valves are designed to be used in a wide range of applications such as the interception of gas or termal oil and for temperatures from -50°C to +400°C.

The AP model stands out for its well-known two-piece threaded construction, threaded or welded connections and it is also available with integral non-welded nipples.

Technical features

|

CONSTRUCTION

|

Floating Ball,Full Bore , 2-piece threaded

|

|

DIMENTION RANGE

|

DN 1/2” – DN 2” |

|

PRESSURE CLASSES

|

800Lb – PN 138 |

|

TEMPERATURE RANGE

|

-50°C / +400°C |

| DESIGN STANDARD | ASME B16.34 / EN17292 / ASME VIII DIV.1 / EN 12516-1 / API608 |

| FACE TO FACE | Std. Penta |

|

CONNECTIONS

|

NPT (ASME B 1.20.1) / SW (ASME B 16.11) / BW (ASME B 16.25)

|

|

BODY MATERIAL

|

A105 / A350 LF2 / AISI 316 / AISI 304 / other materials on request |

|

SEATS

|

PENTAFITE / WC / CRC / ST6 / RPTFE /PEEK |

|

STEM DESIGN

|

ANTI BLOW-OUT |

| MOUNTING | ISO 5211 |

|

TIGHNESS CLASS

|

ASME B16.104 / API 598 Cl. A / EN 12266-1 / ISO 5208 / BS 6755-1 |

EC Directive 2014/68/UE “PED”

EC Directive 2014/34/UE “ATEX”

SIL3 IEC61508

The double ring system with loading nuts allows the correct stem gasket pre-loading and the adjustment to recuperate wearing and clearance for different thermal dilation between stem an body

GASKETS

Only Grafoil® gaskets are used, inherently resistant to high temperatures: no polymers are used

STEM

Stems are 100% oversized against expected torque at max. rating DP.

BOLTING AND FLANGES

All flanges connections are designed according to ASME VIII Div.1 and ANSI B16.34.

BALL

Very high precision grounded balls are produced inside and then they are hard coated with most advanced systems

SEATS

Metallic seats are pre-loading with springs for a perfect low pressure bubble tightness and to recuperate life wearing and different thermal dilatation between internals.

Suitable for a wide range of services with working temperatures from -50°C up to +400°C, can be equipped with metallic seats in Pentafite to allow the manufacturing of metal seated ball valves with absolutely ZERO LEAKAGE, with easy maintenance and 40% lower torques when compared to other metal seated valves.

TUV certifications according TA-LUFT or ISO 15848-1 are also available.

| INTERVALLO DI PRODUZIONE | |

|---|---|

| Ancora in fase di modifica | |

| ANSI B 16.34 | 800 |

| PN | |

| Diametri Nominali | F |

| ½” | |

| ¾” | |

| 1” | |

| 1¼” | |

| 1½” | |

| 2” | |

| 2½” | |

| 3” | |

| 4” | |

| 6” | |

| 8” | |